Materials, Substances & Surfaces

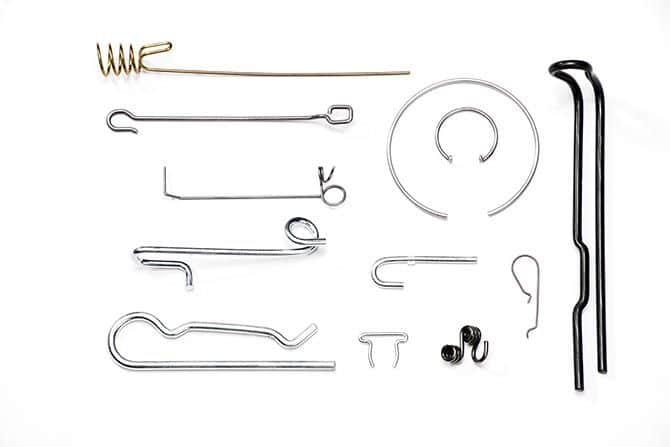

We can process a wide range of different materials for compression springs, extension springs, torsion springs, snap rings, wire formed parts and stamped parts. We also offer a large selection of surface treatments for these products.

We’re happy to advise you.

If you require specific materials or surface treatments or finishes for your products, feel free to contact us — we’ll be happy to assist you.

Springs

We use the following materials for the production of technical springs:

- Spring wire EN 10270-1 (SM, SH, DH)

- Spring wire EN 10270-2- (CrSi alloyed, CrV alloyed)

- Spring wire EN 10270-3 (1.4310. 1.4571, 1.4568, etc.)

- Special materials (bronze, brass, Inconel, etc.)

- All materials can be processed in round wire or profiled wire versions

Wire Formed Parts

- Spring wire EN 10270-1 (SM, SH, DH)

- Spring wire EN 10270-2- (CrSi alloyed, CrV alloyed)

- Spring wire EN 10270-3 (1.4310. 1.4571, 1.4568, etc.)

- Special materials (bronze, brass, Inconel, etc.)

- Additionally: Steel wire

- All materials can be processed in round wire or profiled wire versions

Stamped Parts

- Spring steel EN 10132-4 (C60C, S75S, etc.)

- Spring steel EN 19151 (1.4310, 1.4568, 1.4401, etc.)

- Steel strip ST 37, St52, QSTE380, etc.

Surfaces / Surface Treatment

Thanks to long-standing partnerships with qualified companies, we can offer you an extremely wide range of different surfaces. We can offer you the following processes, treatments and finishes:

- Electrogalvanizing with all chromatizations

- Copper plating

- Burnishing

- Zinc flake coatings (Delta Tone/Delta Seal)

- KTL coatings

- Phosphating

- Dacromet coatings

- Painting

- Processing of commercially available, coated spring wire

- Shot peening

Our Service Promise:

Versatile, Flexible and Punctual.

Thanks to our modern and versatile machines, many years of experience and qualified employees, we are able to manufacture a wide range of technical springs, such as compression springs, torsion springs, extension springs, snap rings, stamped parts and wire formed parts.

Our machinery is not only versatile, but our own toolmaking and our commitment to flexibility ensure that we are agile and fast in production.

Whether it is the short-term production of a product sample, a small series or a large series, we always offer the right solution.

We are aware that on-time production is of utmost importance to our customers and ensure that we always deliver on time, even with high versatility and flexibility.

Our raw material warehouse enables us to quickly and efficiently provide a wide range of standard materials for production. If it is a special material, we have close relationships with suppliers who can quickly provide us with the required material.